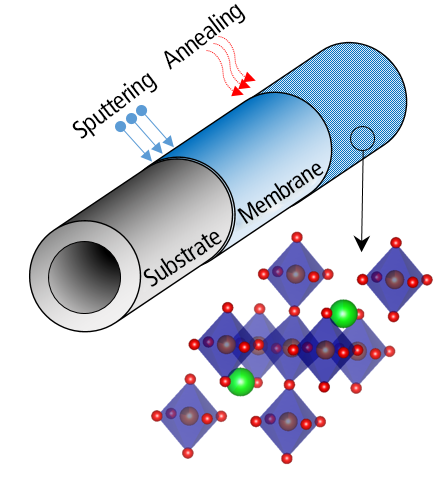

CF05: Electroceramic thin films for the use of ammonia in marine propulsion systems

Thin films CF05 Project costs: 1.193 T€ Project period: 09/2020–08/2022 Partners: Objective: The consortium for the collaborative project CF05 is developing a quick-start membrane reactor for the production of hydrogen from ammonia. This is a key hydrogen technology for efficient energy conversion in different types of fuel cells and engines in the future. In contrast…