The subproject CF08_2 will realize the demonstration of the propulsion system for an inland waterway vessel, which is operated with ammonia as fuel. For stable ignition of the ammonia-air-mixture in the engine, as a novelty in this project, a partial stream of the ammonia is passed over a cracker before the engine, where it is dispersed into hydrogen and nitrogen. The addition of a certain amount of hydrogen helps in the combustion chamber of the engine to ignite and completely burn the sluggish-ignitable ammonia.

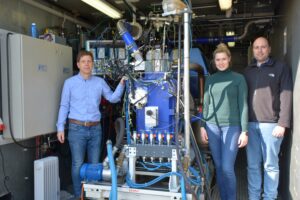

Fundamental research into this combined ammonia-hydrogen combustion process is an important component of the CF08_2 subproject. For this purpose, a single-cylinder research engine was set up in Karlsruhe at KIT, which represents the process of one cylinder in the future ship propulsion system under laboratory conditions. The experimental setup makes it possible to vary the mixing of air with ammonia and hydrogen in various ways and to study the effects on combustion and pollutant formation. The ammonia can be supplied either in liquid or gaseous form.

For the experimental set-up in the laboratory, similarly complex safety considerations have been established as those that have to be made in an inland waterway vessel. Protecting people and the environment when handling ammonia is also a new challenge for the researchers. Important pioneering work has already been done here for the test setups at the further test sites within CF08_2 and for use onboard a ship, too.

After intensive preparation, the test setup was successfully commissioned in February 2023 and the engine operated for the first time with a combined hydrogen-ammonia combustion for several hours. Variants and conversions will follow in the coming weeks and months to answer the following questions:

- What is the minimum hydrogen content required, and what is the maximum H2 content that can be tolerated for all operating points relevant for ship operation? This is an important parameter for the design of the upstream cracker, whose dynamics are different from those of the engine.

- Which locations on the engine are optimum to supply the hydrogen and the ammonia? Which aggregate state of the ammonia is best? Which injection pressures are most suitable?

- Which compression ratio and which amount of air represent the best compromise in terms of maximum efficiency and minimum pollutant emissions?

- Which design has to be applied to the engine components to withstand the demands of the multi-cylinder-engine-tests in Rostock?

The results of the work on the research single-cylinder engine will be continuously communicated within the subproject and will be incorporated into the experimental setup and research test runs in Duisburg and Rostock.