In accordance with the roadmap developed by CAMPFIRE, cost-optimised production methods for the basic innovations are currently under development – a precondition for introducing technologies to the market for the global ‘green ammonia ecosystem’ of the future. These innovative technologies include electroceramic thin films and catalysts, reactors and synthesis plants for the seasonal production of ammonia, ammonia crackers for hybridisation with gas engines, and fuel cells for stationary power generation and emission-free propulsion in shipping.

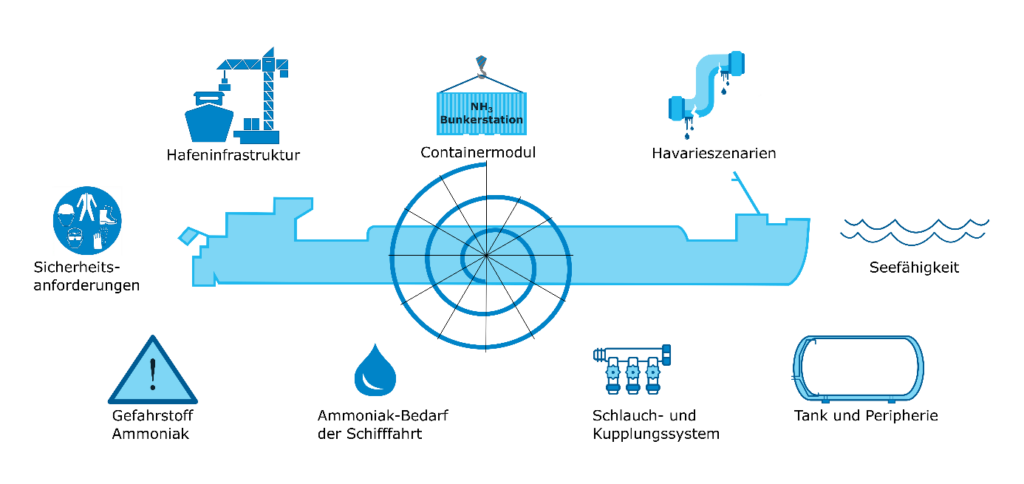

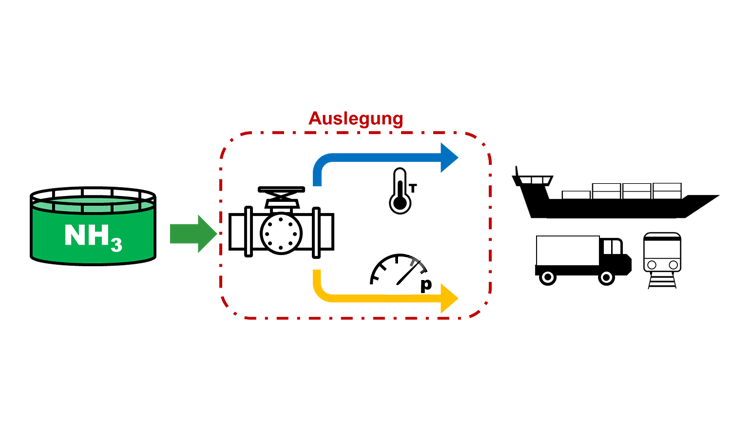

CAMPFIRE is also developing ammonia refuelling systems and shoreside and seaside safety systems, including sensor technology for the application of ammonia drives on board yachts, inland vessels and seagoing vessels. As part of its work on this topic, the consortium is examining and elaborating the existing legal framework for the implementation of the new technologies, and approaches are being developed to increase public and customer acceptance of ammonia as an energy source.

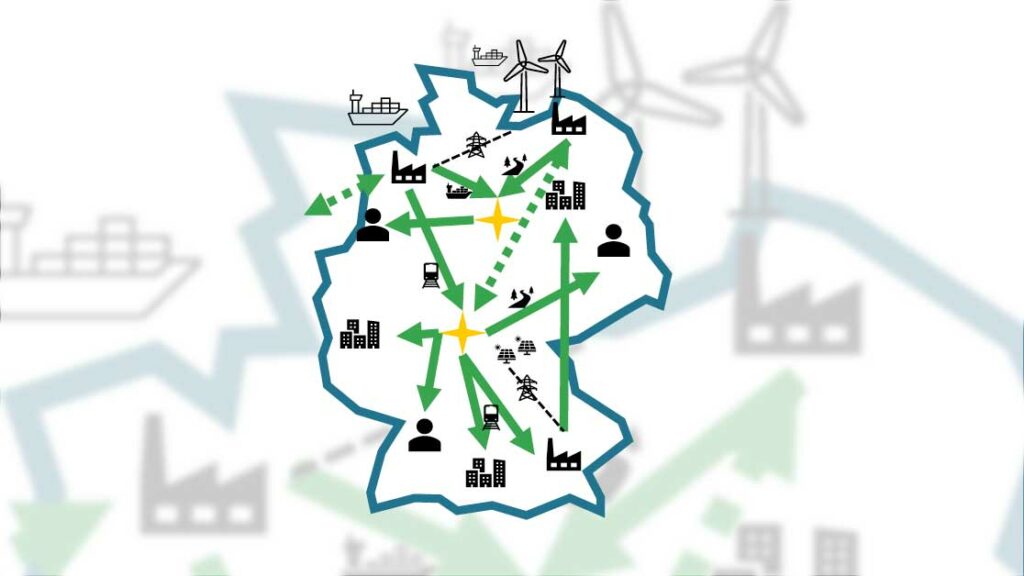

Logistics and infrastructure concepts are being developed to facilitate the distribution of green ammonia from imports and regional ‘green ammonia farming’. Standardisation, norming and certification, and approaches to train experts are also a focus .

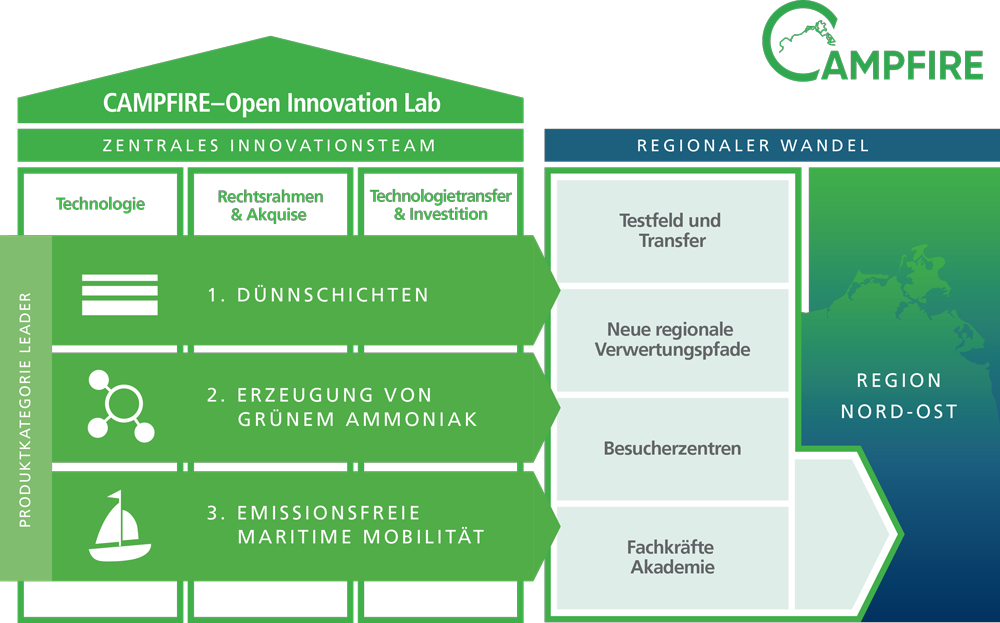

In order to implement the objectives, the CAMPFIRE alliance combines expertise in natural, engineering, legal, economic and climate policy, and takes an agile open innovation management approach to project development.

Thin films

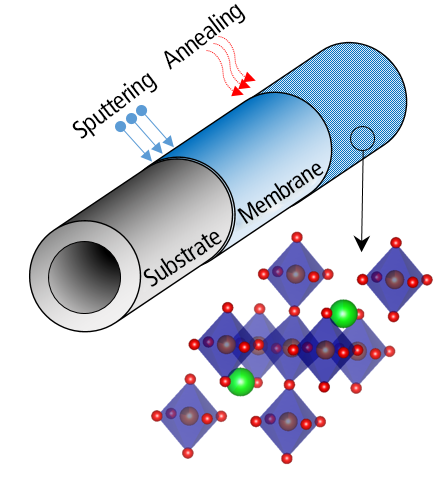

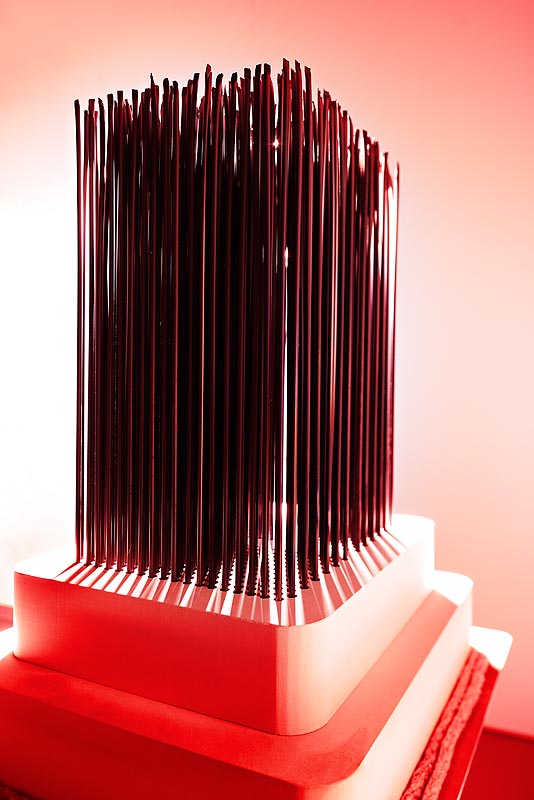

At the heart of CAMPFIRE energy technologies are electroceramic membranes with perovskite structures, which are thinner than a millionth of a metre and can be manufactured in a process that is cost-effective and resource efficient. Perovskites provide significant benefits thanks to their high-temperature electrolyte materials, mechanical load-bearing capacity, physical-chemical properties and temperature resistance and are able to conduct oxygen ions, protons and electrons.

Deposition process used to manufacture industrial electroceramic thin-film membranes.

Green ammonia

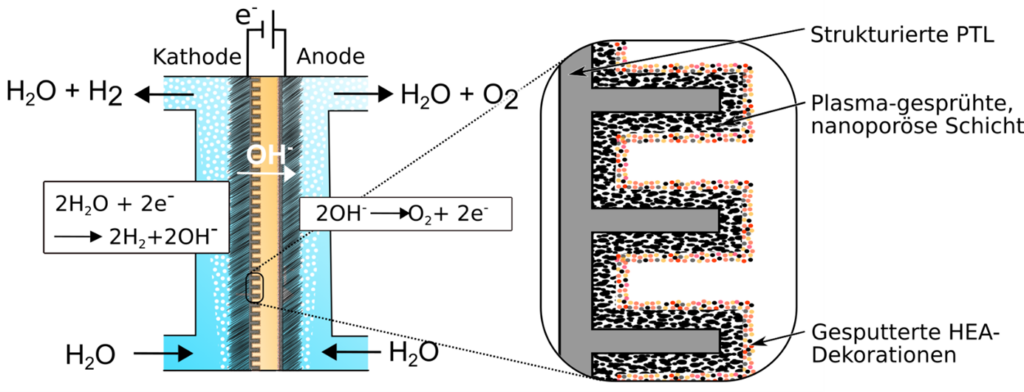

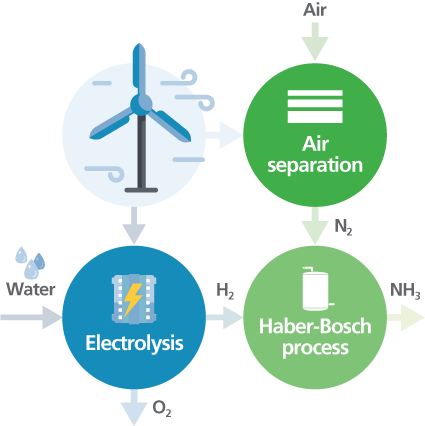

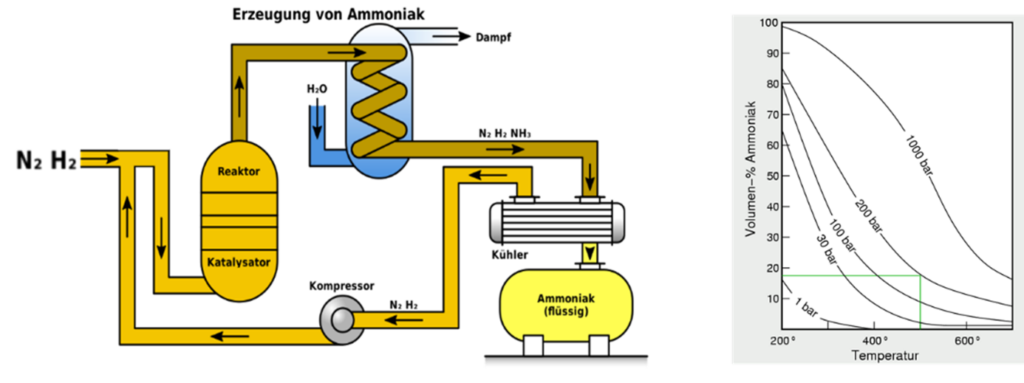

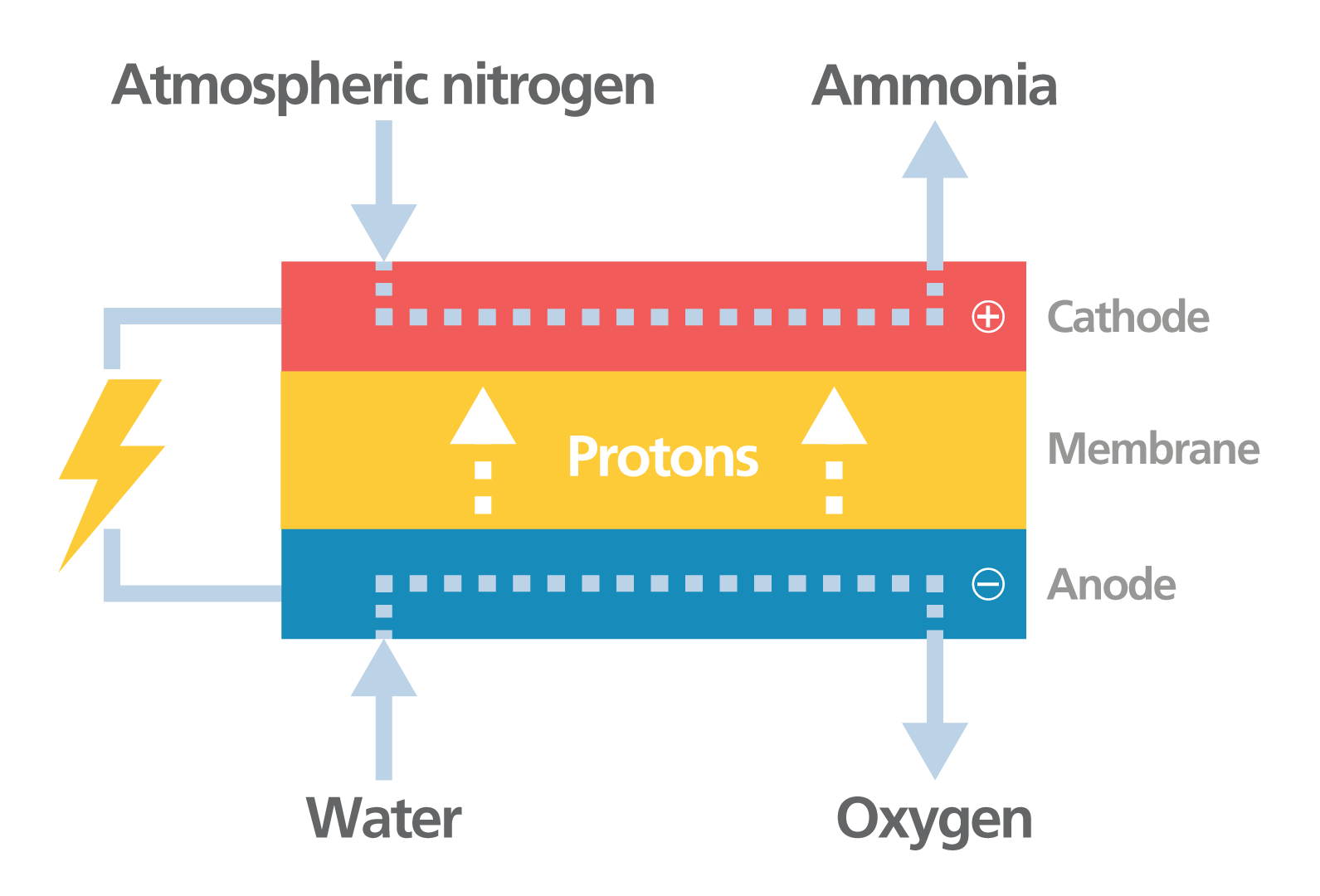

In the future, conventional international methods for ammonia synthesis, which are based on fossil fuels, will be replaced and decentralised. This will make direct ammonia production from renewable sources economically feasible on an industrial scale. The CAMPFIRE project is developing innovative energy technologies with high process efficiency and low costs for ammonia synthesis from renewable energy sources. Mixed-conducting oxygen separation membranes can be used to provide nitrogen from ambient air, which is available everywhere. Green ammonia can be produced efficiently in a decentralised manner using a micro-Haber-Bosch process in the presence of high-volume flows from wind or solar power. Proton-conducting membranes enable an efficient solid-state ammonia synthesis process (SSAS) for the formation of ammonia from nitrogen and water vapour. In the future, SSAS will be a cost-effective and energy-efficient alternative to the Haber-Bosch process.

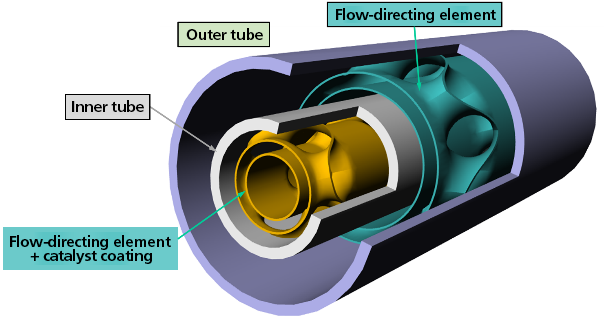

Proton-conducting membranes for the direct synthesis of ammonia from atmospheric nitrogen and water vapour (SSAS).

Marine propulsion

Green ammonia makes it possible to decarbonise maritime shipping. At normal temperatures, it can be liquified at a pressure as low as 8 bar (-33°C at normal pressure), which allows for easy storage and transport. Ammonia contains approximately 17% of hydrogen and has an energy content comparable to that of methanol. Our approach is two-fold: to use ammonia directly or partially converted to hydrogen in combustion engines and gas turbines, and to directly convert ammonia or hydrogen into electricity in a fuel cell for marine shipping. When conventional NOX emission control appliances such as SCR are used, the end products are only water and hydrogen, which can be returned to the air safely.

Stationary energy

Infrastructure and logistic

Legal framework and acceptance

CAMPFIRE Open Innovation Lab