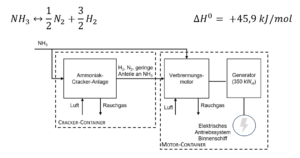

In order to speed up the decarbonization of shipping, the CF08_2 project is developing an ammonia-powered, containerized inland vessel propulsion system with 350 kW propulsion power and evaluating it ” on-land”. Figure 1 shows a schematic representation of the propulsion system. To improve the ignition and efficient conversion of the ammonia in the engine, a certain proportion of hydrogen is also required in the fuel. For this purpose, an ammonia cracker is connected upstream of the engine, which endothermically splits a partial flow of the ammonia into hydrogen and nitrogen and feeds this mixture to the combustion engine as pilot fuel.

Figure 1: Schematic representation of the ammonia-powered propulsion system of an inland waterway vessel

Development work at the ZBT

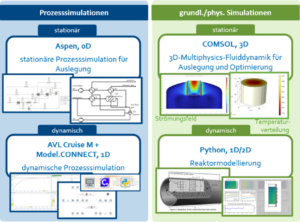

The cracker system is developed, designed and built by ZBT and extensively tested and optimized. After successful containerization of the cracker plant, ZBT also supports the coupling with the engine and the operation of the entire system. The system development is supported by ZBT’s own extensive simulation work, in particular for process and reactor design and control development. An overview of the simulation work is shown in Figure 2. 0D simulation in Aspen Plus® is used for process development. The aim here is to implement optimized heat integration and determine all relevant material and energy flows. These are required for the design and selection of plant components such as the reactor, burner, heat exchanger, compressors, etc. The detailed design of the reactor and flow components such as distributor structures is carried out taking into account the reaction as well as material, heat and momentum exchange, supported by 2D/3D multiphysics simulations in COMSOL Multiphysics®. The 0D model from Aspen Plus® is converted into a dynamic and real-time capable model in AVL CruiseTM M for the control development for the automation of the cracker system.For this purpose, a 2D FVM model of the cracking reactor is developed in Python and integrated into AVL using the Model.ConnectTM tool.The dynamic AVL model is used to develop optimized operating strategies, in particular for start-up and shutdown processes and load changes as well as safety-related issues.This enables not only an increase in system efficiency and safety, but also an improvement in operation under variable load and an increase in service life by, for example, avoiding catalyst overheating.

Parallel to the simulation work, an ammonia laboratory infrastructure and test environment is currently being set up at the ZBT, which will make it possible to experimentally examine not only the components of the cracker system individually and in the process technology network, but also the entire cracker system. This will provide extensive experimental data to validate the simulation work.

Figure 2: Use of simulation tools at ZBT for the development and optimization of the cracker system

Potential analysis at LTT

In order to increase the efficiency of the overall cracker and engine system, the Chair of Technical Thermodynamics at the University of Rostock is investigating the possibilities of thermally coupling the engine and cracker system at a theoretical level. The engine has a waste heat potential that is dependent on the operating state. This waste heat potential can be utilized in the cracker and thus reduce the cracker’s external energy requirements. This results in an increase in the efficiency of the overall system. In order to evaluate the various options and carry out optimizations, both a 0D simulation study of the overall system and a detailed 3D simulation of the heat coupling into the cracker are being carried out. Initial results of the simulation of the overall system show the possible potential of heat coupling: an improvement in system efficiency of up to 4 percentage points.

Results and findings from the development work on the ammonia cracker system are communicated on an ongoing basis within the sub-project and thus have a direct influence on the test set-ups and experiments for the research work at KIT in Karlsruhe and the University of Rostock.